Filimi e Ntle e hlakileng ea Kantle le ea Ka tlung ea Eva bakeng sa Khalase ea Meaho

Mokhoa oa tlhahiso

1.Filimi eohle e amohela lisebelisoa tse ncha tsa boleng bo holimo.

Tlhahiso ea 2.Dust mahala workshop

3.Tlhahlobo e thata ea boleng le tlhahlobo

4.Ho paka ka mokotla kapa mokotla o sa keneleng metsi

Tekheniki parameter

| Che. | Ntho ea teko | Sephetho sa teko |

| 1 | Matla a tšepe | 8.1 MPA |

| 2 | Ho khomarela ka khalase | 99.7N/cm(180° ho ebola) |

| 3 | Ho khomarela ka organic polymer fim | 21.3N/cm(180° ho ebola) |

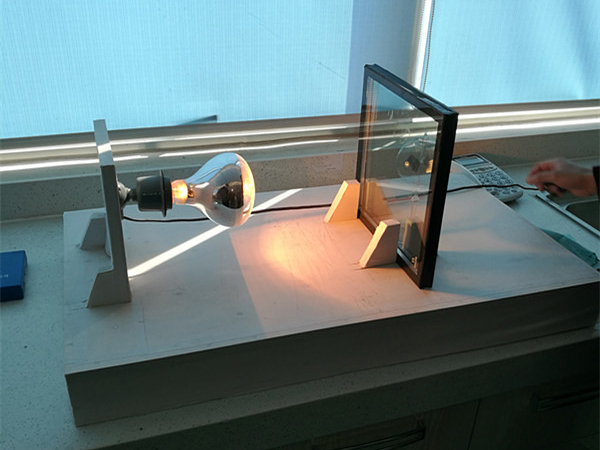

| 4 | Phetiso ea khanya | ≥90.5% |

| 5 | Haze | 0.47% |

| 6 | Sekhahla se koetsoeng ke UV | 90% |

| 7 | Elongation | 800% |

| 8 | Ho honyela | ≤5% |

| 9 | Ho monya metsi | ≤0.01% |

| 10 | Ho hanyetsa mocheso (Ka metsi a 100 ° C bakeng sa lihora tse 5) | Ha ho bubble, ha ho de-lamination |

| 11

| Ho hanyetsa mongobo (60°C,95% RH lihora tse 400) | Ha ho bubble, ha ho moholi |

| 12 | Khahlanong le botsofali (RH radiation lihora tse 3000) | Ho fetoha ha leseli ≤3.0%, ha ho na phetoho e mosehla |

| 13 | Ho chesa le ho bata (40°C metsotso e 30 le 80°C metsotso e 30 bakeng sa lidikadikwe tse 50) | Ha ho bubble, ha ho de-lamination |

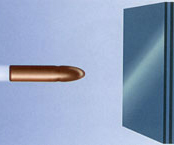

| 14 | Tšusumetso ea ho hanyetsa khahlano le Shot-bag | Ea tšoanelehang |

| 15 | Ho hanyetsa ho phunya ha bolo | Ea tšoanelehang |

| 16 | Bophelo bo molemo | ≥18 lilemo |

Kopo

1. Khalase ea Moralo ea Laminated

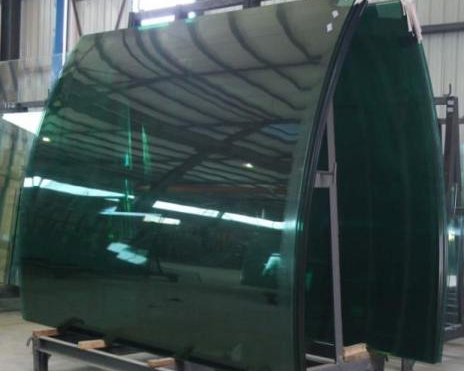

2. Ho haha khalase ea laminated e kobehileng

3. Khalase e thibelang likulo

4. Lipalesa tsa 'nete le masiba le likhalase tsa lekhasi la laminated

5. Mohala le lesela la laminated khalase.

6. Lebala filimi laminated khalase

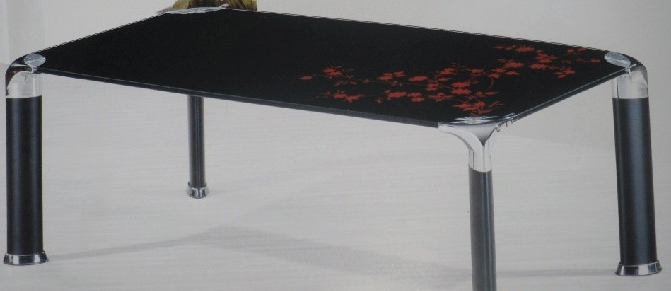

7. Khalase ea tafole ea kofi le khalase ea fensetere ea khabinete

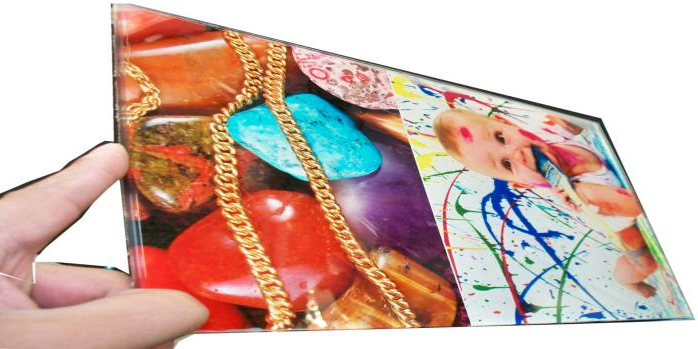

8.Photo le setšoantšo sa laminated khalase.

9. Khalase e halefileng ea laminated le mamati a oteropo.

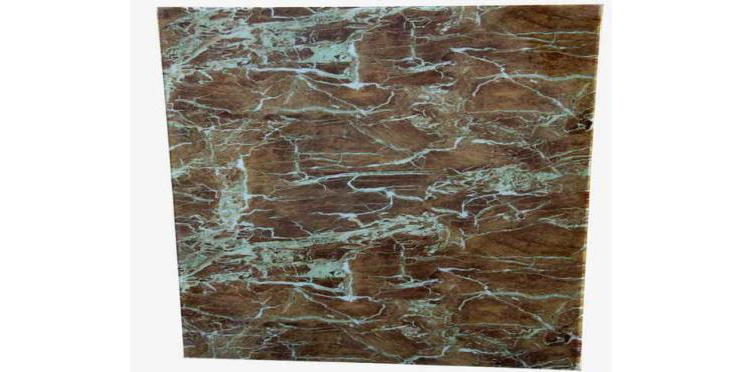

10. Marble laminated glass

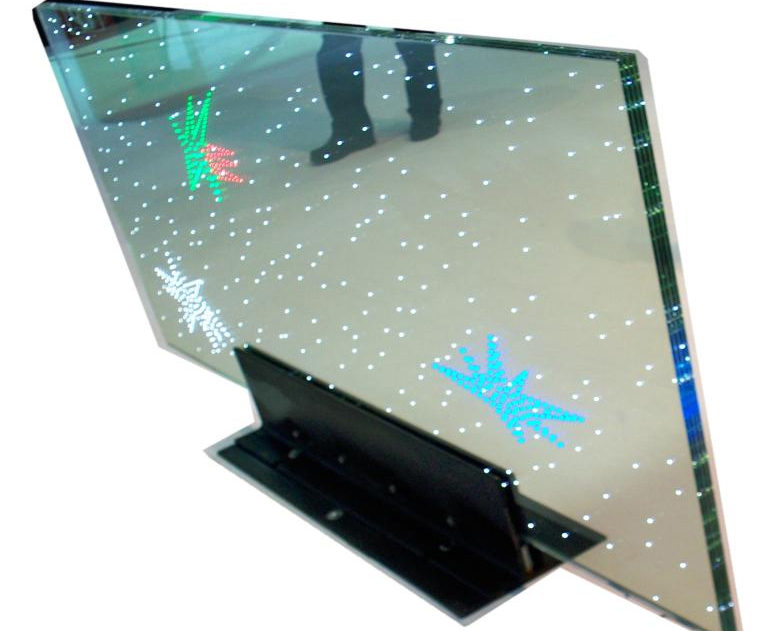

11. Solar PV panels laminated glass, LED khalase le khalase ea motlakase.

12. Khalase ea lekunutu ea Polyvision

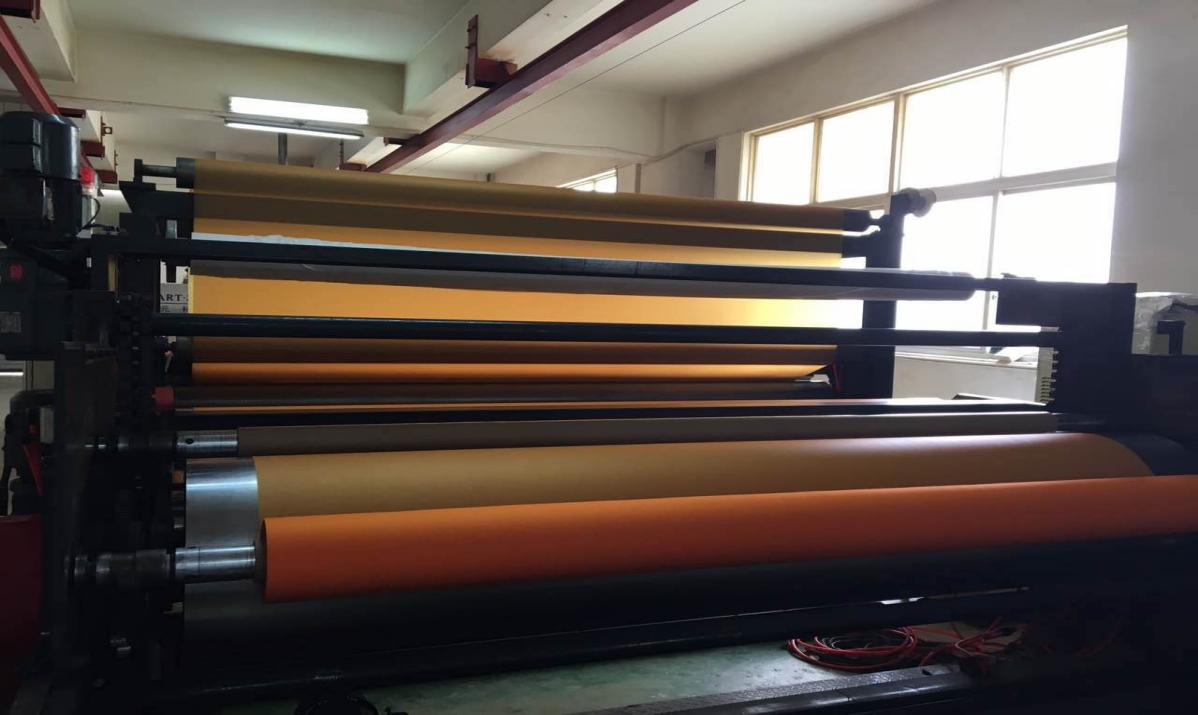

Workshop

E kenya litšoantšo

Semela sa bareki

Khotsofalo ea bareki

Ngola molaetsa wa hao mona mme o re romele wona